Assembly integration can be complex and for growing businesses, a top priority is eliminating confusion and optimizing efficiency.

During our recent webinar in July, we discussed how our assembly integration solution powered by Aras Innovator can streamline the assembly, integration, and testing of systems for the ever-changing technology landscape, including the asset management piece.

The solution aims to meet market needs for an asset management system that restructures the approach to identifying requirements, managing interfaces, and abating risks to reach objectives throughout the intended project lifecycle.

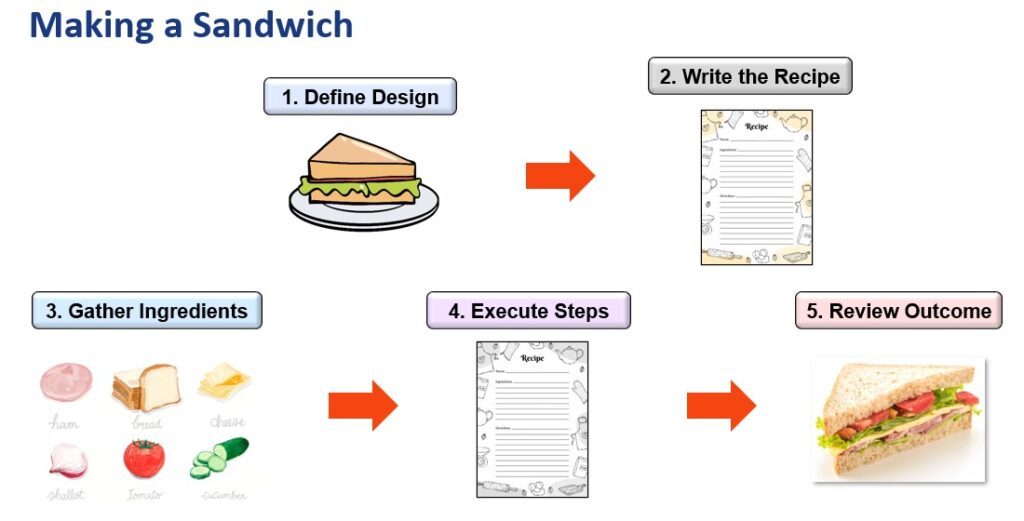

With our AI&T solution, managing these processes has become automated for simplicity. With the help of a simple narrative, the once tiring process becomes five easy steps.

To best visualize the solution and its application, we build a sandwich from start to finish.

Define Design

To begin, we design our sandwich. What do we want? How do we want each layer to sit? What will we need? In this step, we must brainstorm the intended outcome of our assembly integration project and begin determining all necessary steps and ingredients to proceed to the next.

Writing the Recipe

Here, we take all our prior knowledge from the design phase and move it into the recipe phase. We document our intended ingredients, the items per ingredient, and outline and specify steps that are necessary for this project.

Gathering Ingredients

To gather our ingredients, we use our shopping list and check what we have “in-house” at our disposal and use this to revisit and revise our recipe stage. This is an important step before building to ensure that this project can not only be replicated but streamlined for others once written into the system or the final notes section for future tracking and changes.

Execute Steps

Once the ingredients populate in the system, the operation and steps can be executed and tracked for future changes and replication. This record allows for the information to be captured and referenced for future work, an integral part of asset management.

The AI&T solution allows for even minute details to be input, such as the type of material, the thickness, weight, whether it has been pre-assembled or remains in its raw form for further traceability, and documentation.

Now, we can execute the steps and assemble the sandwich with full assurance that all steps are correctly documented, and all ingredients are accounted for.

Review

With our sandwich now assembled, if we wanted to go back and make it again or make something similar, we can simply revisit the program and find the execution record. From there, we can view each step and the automation record per ingredient and step in the overall recipe build. Then we can edit steps and track the changes via redlining for detailed modification.

At the end of this process, alongside your sandwich, our program also releases a technical data package of your program in Word with configurable and flexible output formatting with your final as-built configuration.

While we used a sandwich for our demo, this program can be applied to projects in varying sizes and complexities.

Please feel free to contact us for a free consultation or demonstration for your specific needs. Or if you would like to see more of our work, you can view a demo of the solution as well.