Product Lifecycle Management (PLM) is a critical process that guides a product from conception to disposal. With the advent of digital transformation, the concepts of Digital Thread and Digital Twin have emerged as game-changers in PLM. Together, they create a comprehensive view of a product’s physical and digital aspects, enhancing product performance analysis with real-world data, and supporting simulation scenarios for improved product development.

Unifying Digital Thread and Digital Twin in PLM

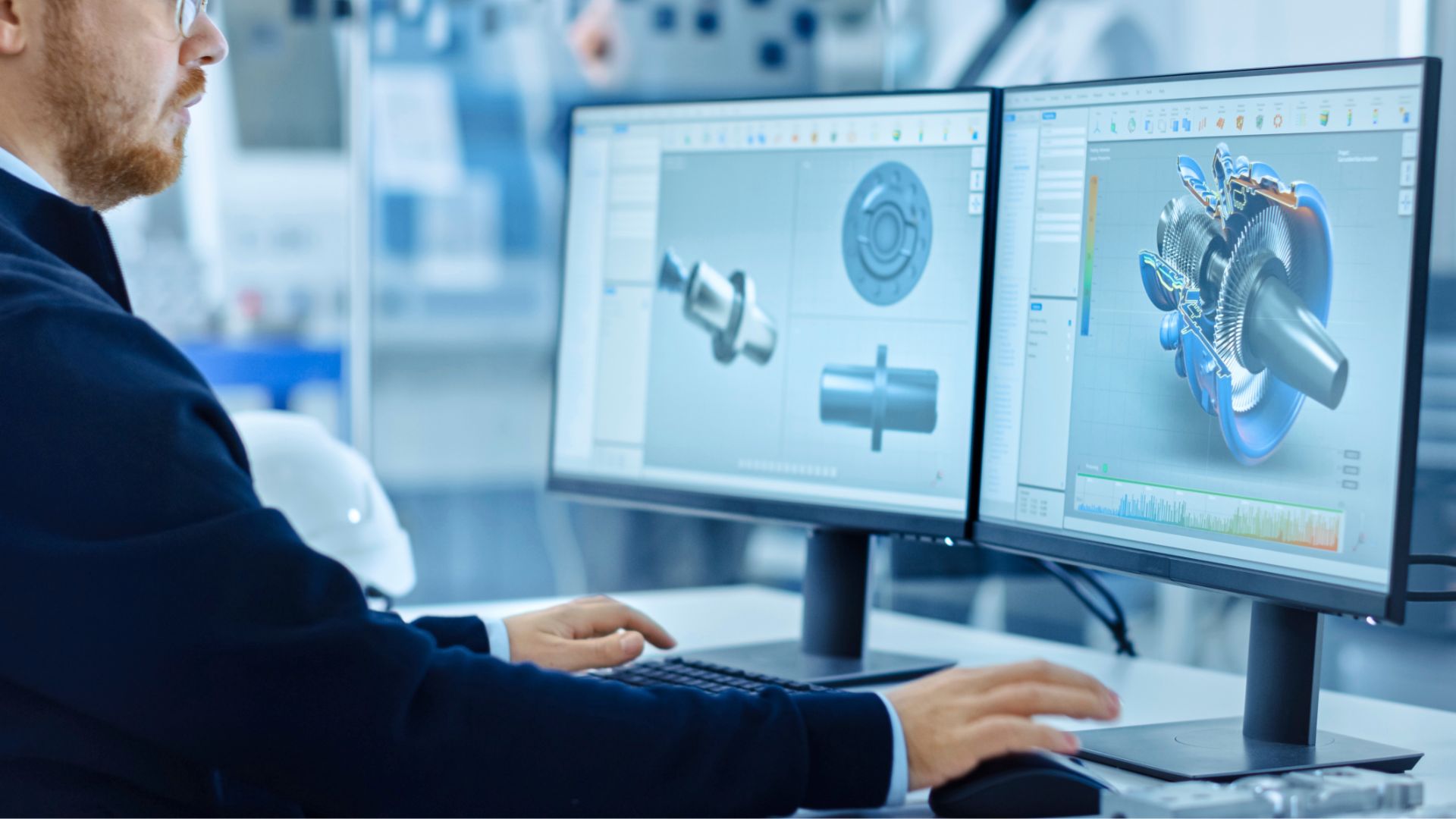

The integration of the Digital Thread and Digital Twin in PLM forms a cohesive framework that offers a 360-degree view of the product. The Digital Thread serves as the backbone of this approach, providing a data-driven story of the product’s lifecycle. Meanwhile, the Digital Twin complements the Digital Thread by simulating the product’s behavior under various scenarios.

This unified platform improves product performance analysis by leveraging real-world data from the Digital Twin. As a result, companies can anticipate product behavior, validate designs faster, and make better-informed decisions regarding product enhancements. By integrating these concepts, organizations gain a holistic understanding of their products. This understanding empowers them to manage and optimize the entire lifecycle of their products from inception, through design and manufacture, to service and disposal.

Comparing Digital Thread vs Digital Twin

While the Digital Thread and Digital Twin are often used interchangeably, they have distinct roles in Product Lifecycle Management (PLM).

The Digital Thread serves as a comprehensive data framework that maps and traces product data throughout its entire lifecycle. It provides visibility into the product’s history, from design to manufacturing and beyond. By leveraging the Digital Thread, organizations can gain insights into the product’s origins, changes made over time, and the associated processes and stakeholders. This visibility enables better decision-making, enhanced collaboration, and improved traceability.

On the other hand, the Digital Twin is a dynamic digital replica of the physical product. It simulates the behavior and performance of the product under various conditions, allowing organizations to virtually test and analyze its functionality. By creating a Digital Twin, companies can gain valuable insights into how the product will perform in real-world scenarios, optimize its design, and identify potential issues before manufacturing.

While the Digital Thread focuses on mapping and tracing product data throughout its lifecycle, the Digital Twin emphasizes creating a virtual representation of the product to simulate and analyze its behavior. Together, these concepts enable organizations to achieve a holistic view and control over the product lifecycle, harmonizing the physical and digital aspects of the product. This integration drives innovation, efficiency, and improved decision-making in product development and manufacturing.

The Role of Digital Thread Engineer

The Digital Thread Engineer plays a pivotal role in establishing and maintaining the Digital Thread within PLM. This professional ensures the accurate mapping of product data throughout its lifecycle, enabling data-driven decisions in product design and manufacturing.

By overseeing the Digital Thread, the engineer facilitates seamless data integration, ensuring that all stakeholders have access to relevant, up-to-date information. This role is crucial in promoting transparency and collaboration, leading to improved product quality and reduced time-to-market.

Digital Thread Manufacturing: A Game-Changer in PLM

Digital Thread Manufacturing is a game-changer in the world of PLM. By seamlessly integrating data, it revolutionizes manufacturing processes and takes product quality to new heights. With its early issue detection capabilities, it minimizes waste and maximizes efficiency.

But that’s not all. Digital Thread Manufacturing also aligns perfectly with the principles of lean manufacturing, optimizing resource utilization and driving cost savings. It’s a transformative approach that empowers companies to elevate their product lifecycle management strategies. In today’s competitive landscape, staying ahead requires innovation and adaptability. Embracing Digital Thread Manufacturing is the key to unlocking operational excellence and propelling your company towards success. Experience the future of manufacturing now!

Harnessing Digital Thread Tools

Digital Thread tools are essential for capturing, managing, and visualizing product data. These tools enable companies to track and analyze product information throughout its lifecycle, facilitating informed decision-making and continuous improvement. Several digital thread tools facilitate data capture, management, and visualization. These tools enhance the effectiveness of PLM by providing a clear and accurate view of product data. They enable organizations to track and manage their products throughout their lifecycle, thereby improving efficiency and reducing errors.

Digital Thread tools are of paramount importance for a manufacturing company as they provide a comprehensive, real-time view of a product’s lifecycle, from initial design to final production and beyond. These tools streamline the flow of data across different stages and departments, thereby enhancing collaboration and decreasing time to market. By creating a single source of truth, they eliminate disparities in data interpretation and reduce errors, leading to improved product quality. Digital Thread tools facilitate predictive and preventive maintenance by using real-time data from the Digital Twin, leading to reduced downtime and cost savings. They also enable companies to retrospectively analyze a product’s lifecycle to identify opportunities for process improvement and innovation. Digital Thread tools serve as a critical asset in driving operational efficiency, enhancing product quality, and fostering a culture of continuous improvement in a manufacturing company.

Conclusion

In conclusion, the Digital Thread and Digital Twin are transforming Product Lifecycle Management. By providing a comprehensive view of the product’s physical and digital aspects, they enhance product performance analysis and support simulation scenarios for improved product development. Additionally, the role of the Digital Thread Engineer and the use of Digital Thread tools ensure effective data management throughout the product lifecycle. Finally, solutions like PTC’s Digital Thread are revolutionizing PLM by offering end-to-end connected product data management, thereby enabling faster and more informed decision-making. Contact us if you want to experience the power of Digital Thread and take your PLM strategy to new heights. Let’s shape a smarter future together!